King Shocks Springs

Coilover spring with 3.0" internal diameter, available in lengths from 4" to 19.5" with different rates, are perfect for 2.5" Coilovers.

King Shocks' coil springs are made in the United States from the highest quality, high-strength chrome-plated silicon wire.

They are designed and made only for off-road vehicles. Rates, wire diameter and different lengths have been tested live on all types of terrain and have been put to the test in international races such as Baja, Dakar and King Of The Hammers.

The spring rate is a number that represents the amount of force in pounds that it takes to compress the coil 1 inch.

A single rate spring is a spring installed in the coilover that compresses linearly. If the spring rate for that coil is 300lbs per inch then compressing that coil one inch generates 300lbs., two inches generates 600lbs., 3 inches equals 900lbs.

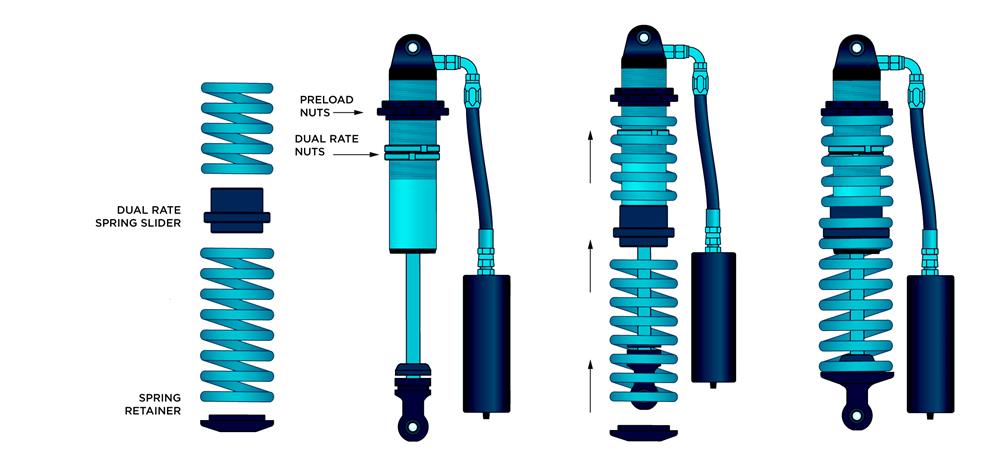

You can also have a dual rate spring which is two coils mounted to the shock. If the spring rates are equal on both coils your spring rate will be close to half that of each spring. As the coils compress equally the shock travels one inch but each coil only travels one half inch. Using our 300lb spring rate in the previous example if you have two 300lb springs and they each travel ½ inch then their combined force would be 150lbs.

More sophisticated double-speed springs can be had that use combinations of springs with different rates to provide nonlinear spring rates, better known as "variable pitch." They can be initially softer and then reach higher levels of stiffness than a linear spring of the same length.

From the menu above make the desired choice considering that the 100lb/inch load corresponds to about 1.8 kg/mm i.e., the spring sags one mm for every 1.8kg of applied load.

If you have any doubts our staff will support you in choosing, configuring and customizing.

Getting the correct coilover spring preload is the first step in setting up your suspension. So what is preload?

Preload is the initial (pre) tension (load) on your springs before carrying the weight of the vehicle. Coilover spring preload is measured in inches, in other words, how many inches have you compressed the springs before applying weight.

Preload at the coilover should be between ½” and 6” to prevent the springs from coming loose and to ensure proper droop, wheel rate and bottoming control. Less preload gives you better handling and less sag when adding weight but reduces how well the wheel droops over bumps. Common setups should use 1-2″ of preload in the front and 2-3″ in the rear.

When in doubt, shoot for more preload than less. If your suspension isn’t drooping properly into a bump and you’re rebound is correct, try adding more preload with softer rates.

How to calculate preload in new coilovers:

- Start with the springs and shocks installed on the vehicle:

- springs loose

- dual rate nuts high on the body, spring slider not touching dual rate nuts

- screw the preload nut down while gently rattling the springs, when they stop rattling that is zero preload;

- measure and record how many inches of threads are showing above the preload nuts;

- every inch you screw the preload nut down is another inch of preload;

- every inch you screw it up is one inch of negative preload

- screw the preload nut down to give you the target preload;

- adjust the preload up or down to give you the desired amount of shock shaft showing at ride height.

If you have negative preload, or your preload is more than +/-1″ from our target we should swap springs.

Dual rate nuts: allows you to adjust the transition point between the softer upper spring and stiffer lower spring. for most applications, the stop nuts should be positioned about 1 inches abave dual rate slider when the vehicle is at ride height and 2 inches in back.

Preload nut: allows you to adjust the preload on the coilover shock. for zero preload, extend shock completely and have the preload nut resting against the upper spring not allowing the springs to move up or down.